Meyer Smart Series color sorter is designed to accurately sort and separate objects based on color, ensuring impeccable quality control for your business.

SMART Series Rice & Multi-product Color Sorter

KEY COMPONENTS

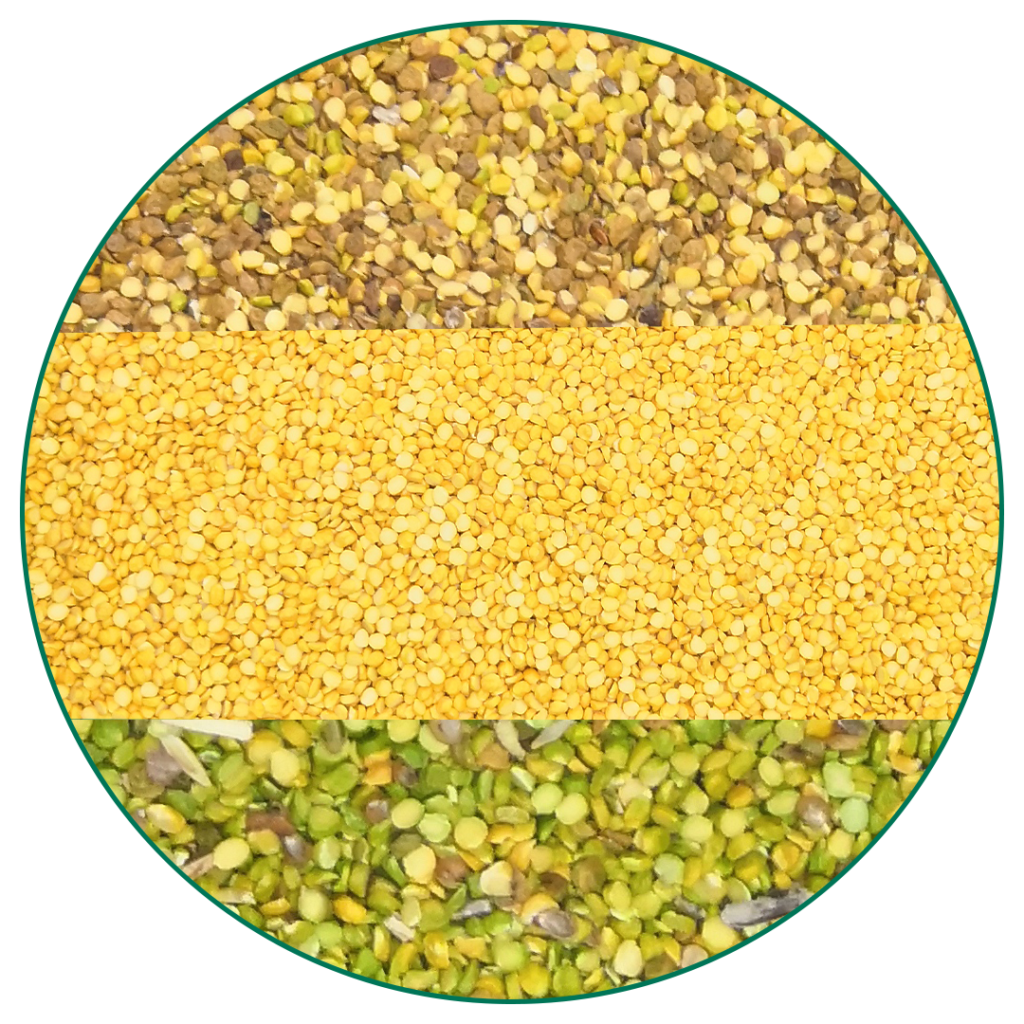

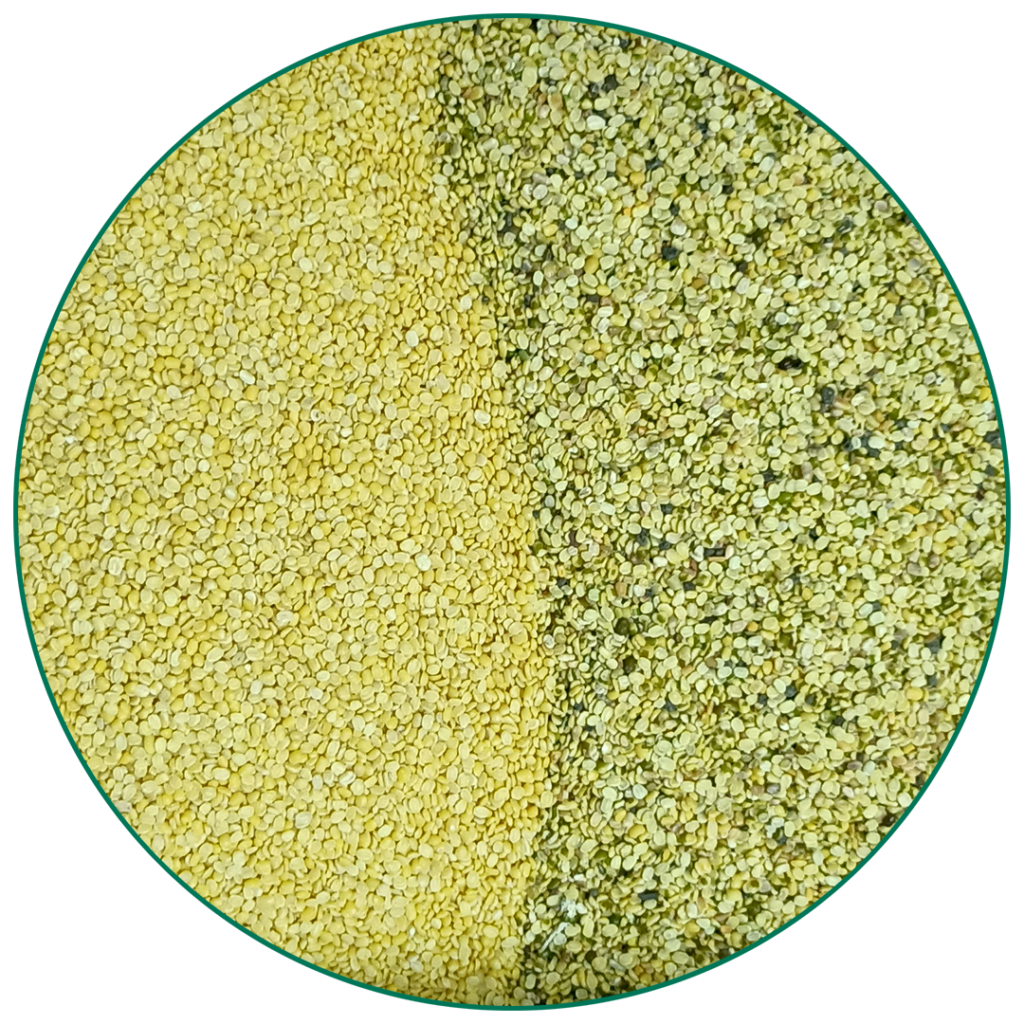

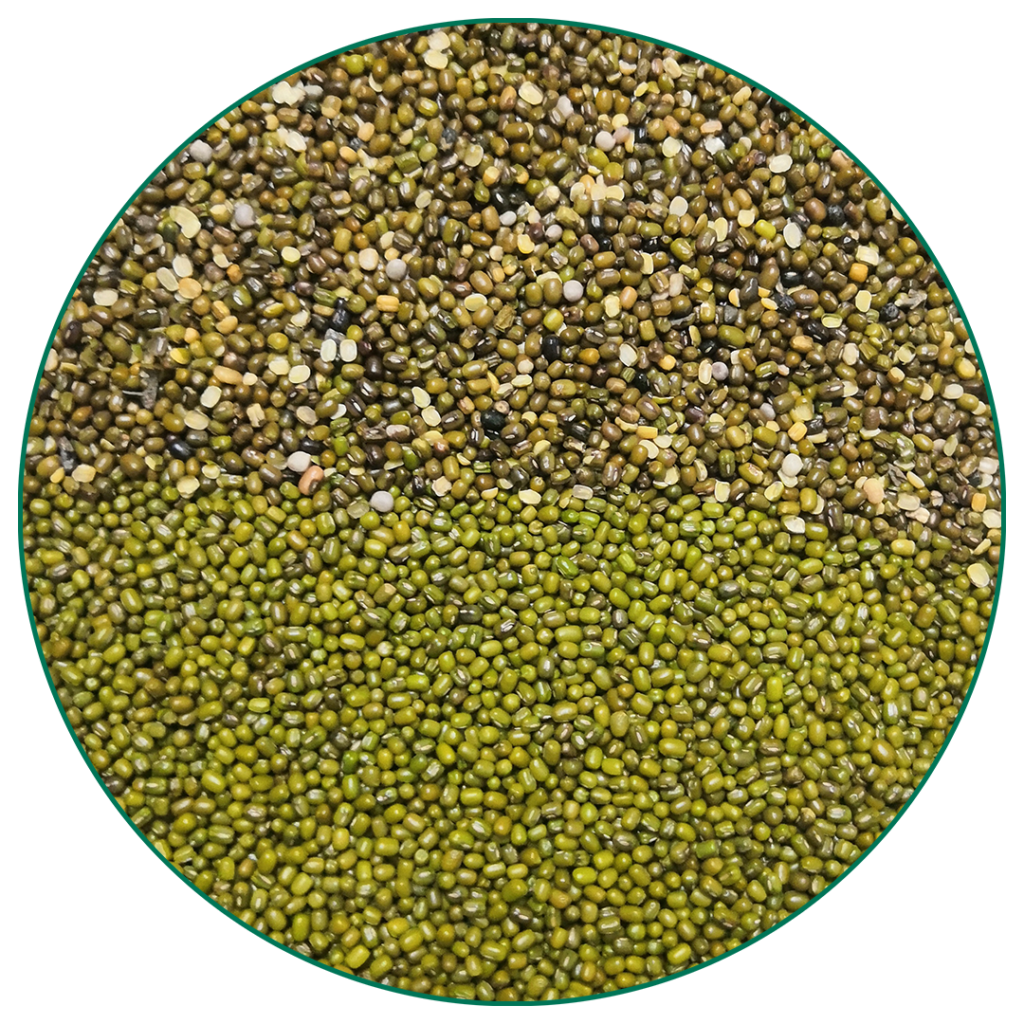

Exclusive color sorting solutions for different raw materials.

-

Highly Pure Rate and Low Loss

Equipped with target positioning to meet the common needs of rice sorting

-

Outstanding Output

Each chute <2.6TPH

-

Shape Sorting

Long/round, large broken/medium broken/small broken

-

Flexible Chute Setting

Tertiary sorting, fourth sorting. fifth sorting, sixth sorting

-

Highly Reliable and Smarter

Standardized and modularized design

-

Spectral Confocal 2.0

The sorting accuracy is auto- matically adjusted

It's mainly used in the sorting of japonica rice, indica rice, glutinous rice, parboiled rice, Sesame seed, pulses, and gram with dozens of intelligent sorting solutions. It features high pure rate, low loss, and stable performance.

RELIABLE COLOR & SIZE SORTING

MEYER CORE TECHNOLOGIES

Nano HD Camera

With the Nano HD Camera, you can rely on enhanced color detection capabilities, enabling the machine to differentiate between subtle shades and accurately sort products accordingly

Maglev Ejector

Ejector is the core part of color sorter, also a quick-wear part for its high operating frequency. Meyer maglev ejector, featuring in long service life and high precision, is your best choice.

Maglev Ejector 3.0

Ultra-high-speed response, shorter start time of ejector for higher accuracy Millisecond-level start and stop, gas supply and cutoff completely, resulting in greater output and lower loss

Shape Shorting

Shape Shorting is a revolutionary feature that streamlines the design process by providing quick and efficient shape optimization.

PID Positiona Control System

The PID Positional Control System utilizes a Proportional-Integral-Derivative (PID) algorithm to continuously monitor and adjust the position of the sorting mechanism.

Full Spectrum Lighting System

The Full Spectrum Lighting System utilizes a comprehensive range of lighting wavelengths to illuminate the product stream as it passes through the sorting machine.

Specification & Configuration

Name | Model | Ejectors | Power | Voltage | Air Pressure (Mpa) | Air Consumption | Weight | Dimension |

240SMART | 6SXZ-240SMART | 240 | 2.0 | 180~240 (50Hz) | 0.6~0.8 | <2.0 | 1110 | 1891×1564×2020 |

360SMART | 6SXZ-360SMART | 360 | 2.7 | 180~240 (50Hz) | 0.6~0.8 | <3.0 | 1380 | 2533×1564×2020 |

480SMART | 6SXZ-480SMART | 480 | 3.4 | 180~240 (50Hz) | 0.6~0.8 | <4.0 | 1730 | 2991×1564×2020 |

600SMART | 6SXZ-600SMART | 600 | 4.0 | 180~240 (50Hz) | 0.6~0.8 | <5.0 | 2070 | 3583×1564×2020 |

ITEM | SMART | ||

Performance | Key Parts | 15-inch LED Screen | ● |

Nanoscale visible light ultra-clear color sensor | ● | ||

Sorting Performance | Capacity of each chute | <2.6TPH | |

Shape Sorting | ● | ||

Full Spectrum Lighting System | ● | ||

Spectrum Confocal System | ○ | ||

Service Life | Maglev Ejector | ★★★★★ | |

LED Light Source | ★★★★★ | ||

Impurity Removal | Glass and Desiccants | ★★★ | |

Air Circuit System | Intelligent Feeder Vaccum System | ○ | |

Auto Cleaning + Anti-Rice Suction | ● | ||

Protection Device | Chute Cover | ○ | |

Intelligence | Intelligent Production Line | Remote Commissioning | ○ |

Meyercare ( App ) | ○ | ||

Parameters above are tested on the environment of 25℃ and 2% impurities rate and may change in different conditions. | |||

REFINED SERVICES

HELP DESK SERVICE

Remote trouble shooting service Online machine adjusting service Faulty escalation service

PRE-SALE SERVICE

Consulting Solution Service Configuration Suggestion Layout Suggestion

ONSITE SERVICE

Onsite routing inspection, Onsite commissioning service, Onsite trouble shooting service, Onsite recovery service

WARRANTY SERVICE

Standard warranty service, Long term warranty service, SLA service, Over warranty service

TRAINING SERVICE

Local training service, High level headquarter service

SPARE PARTS SERVICE

Risky spare part supply, Warranty spare parts service, Key parts maintenance service, Over warranty spare parts service

NICPL

Our Locations

Our Kundli Office

206, Phase 2, HSIIDC, Industrial Area, Kundli, Sonipat, Haryana 131028