Meyer CG.A Series color sorter is designed to accurately sort and separate objects based on color, ensuring impeccable quality control for your business.

CG.A Series Grain Color Sorter

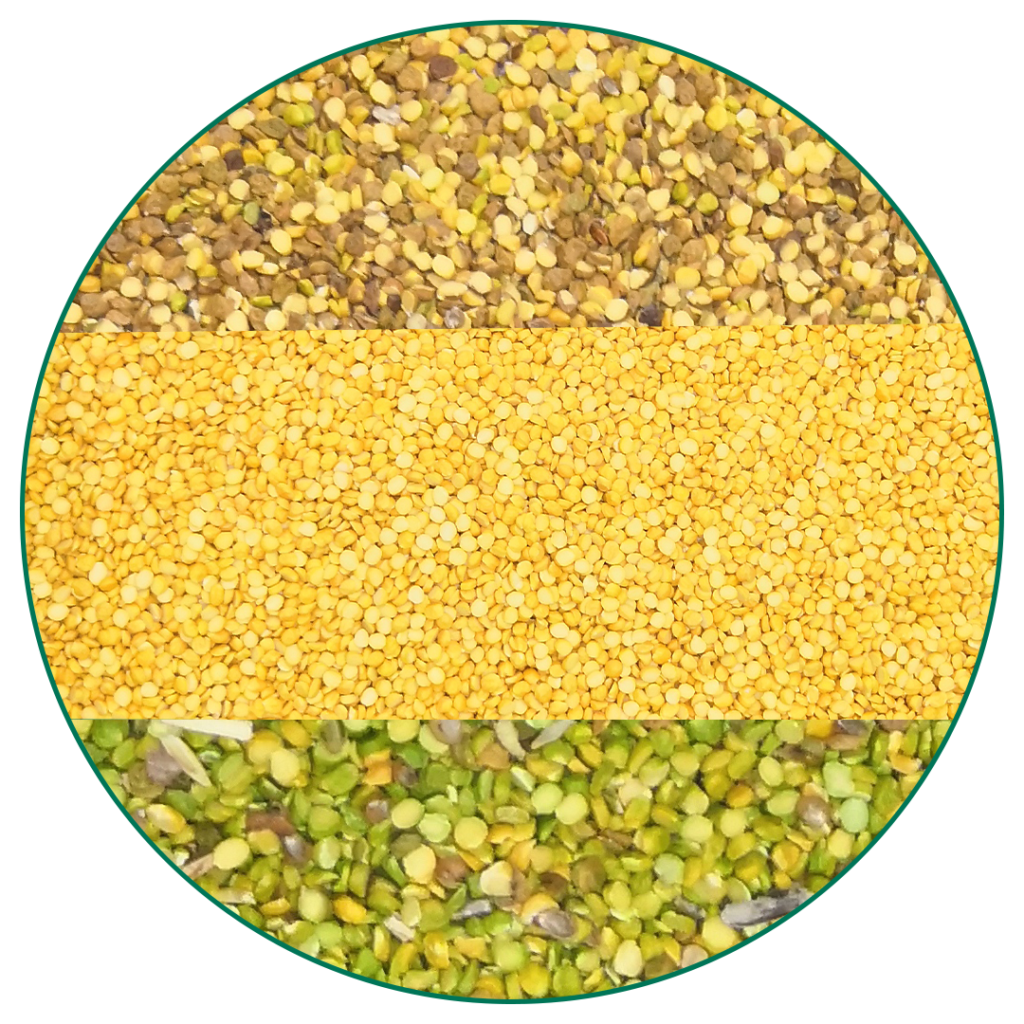

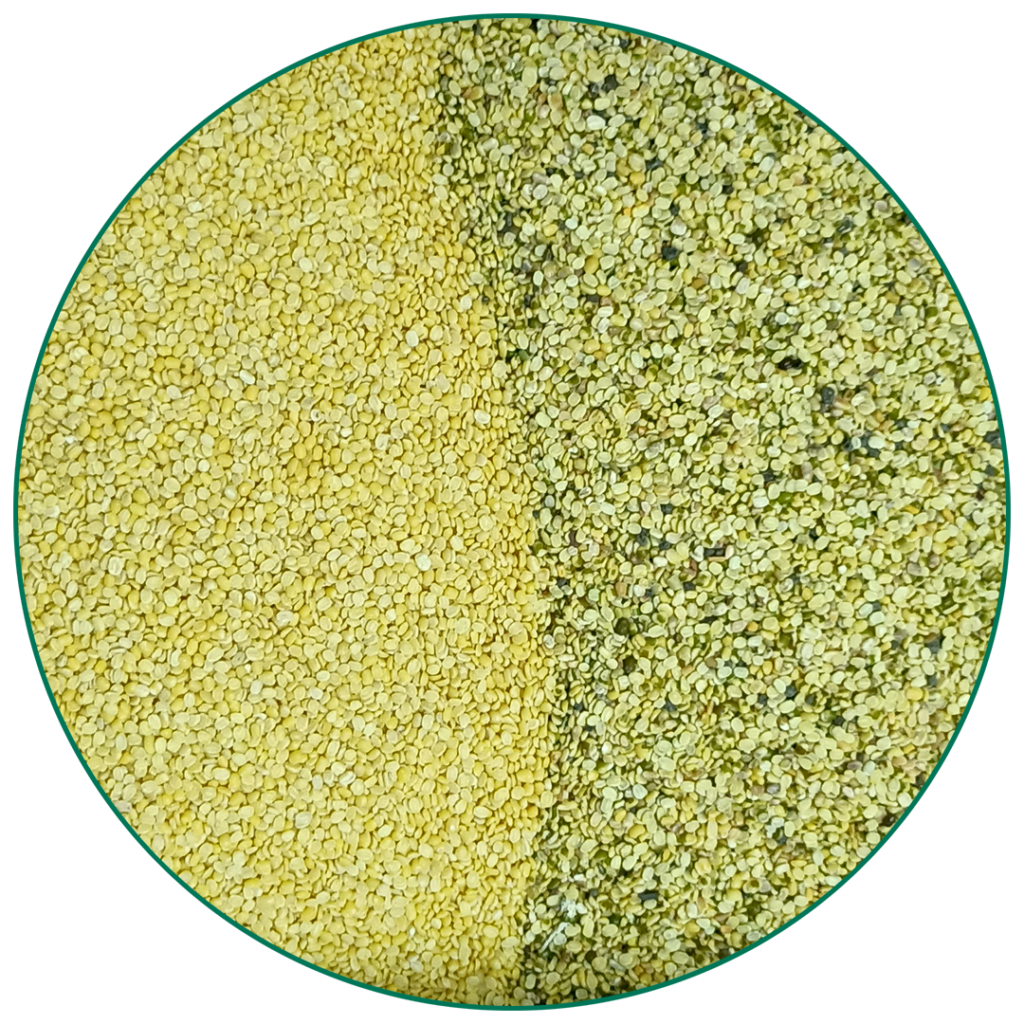

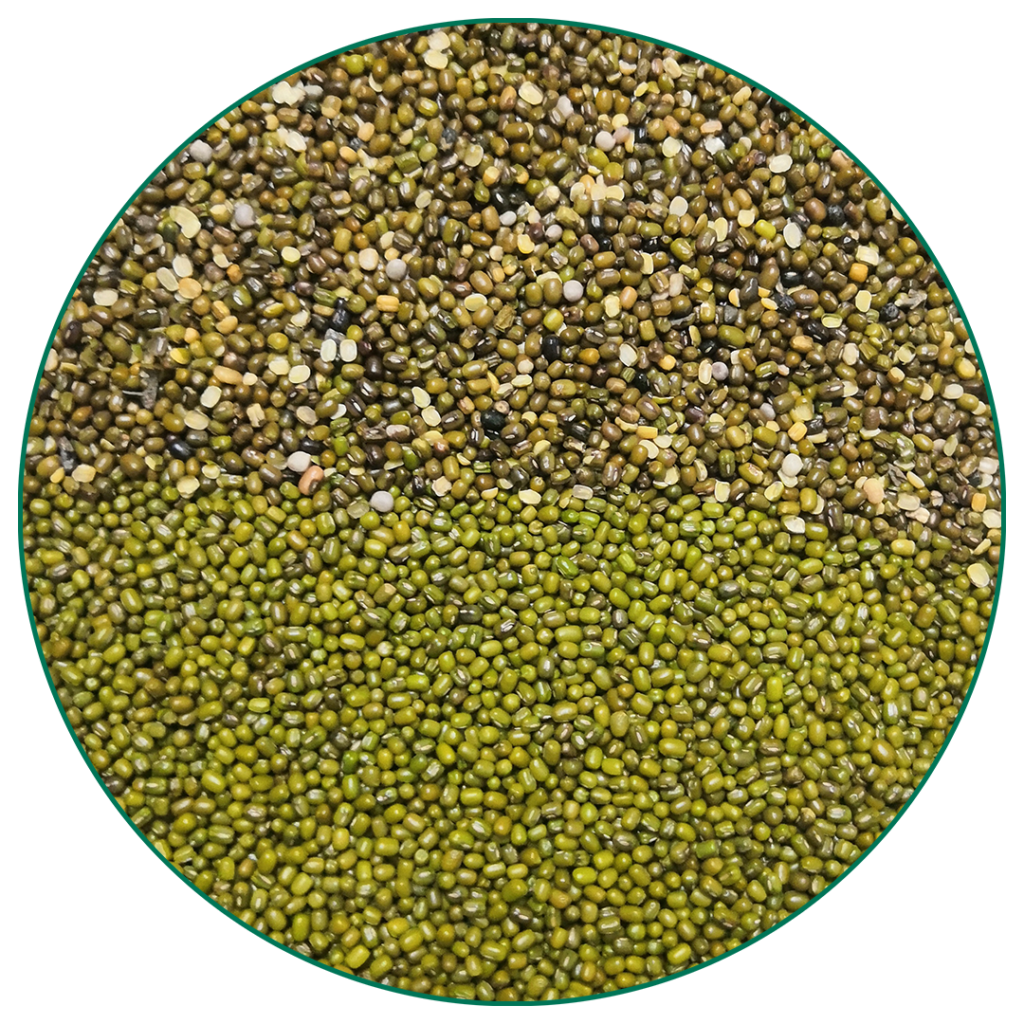

MULTIPLE USAGE FOR MORE CATEGORIES OF GRAINS

-

NIR infrared system/InGaAs infrared system

-

PID Position Control System

-

Color & Shape Sorting

-

Sniper System

-

Crash-prevented System

-

Intelligent Dust Sucking System

-

Easy to Clean

It's mainly used in the sorting of bigger commodities like rajma (Kidney Beans), gram, peanuts, cardimum and pulses with dozens of intelligent sorting solutions. It features high pure rate, low loss, and stable performance

GRAIN SORTING SOLUTIONS

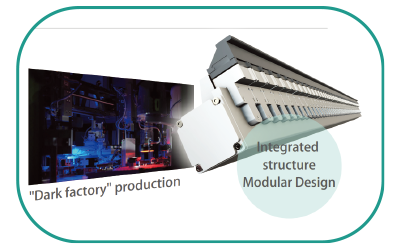

MEYER CORE TECHNOLOGIES

Meyer Maglev Ejector 3.0

Ultra-high-speed response, shorter start time of ejector for higher accuracy Millisecond-level start and stop, gas supply and cutoff completely, resulting in greater output and lower loss

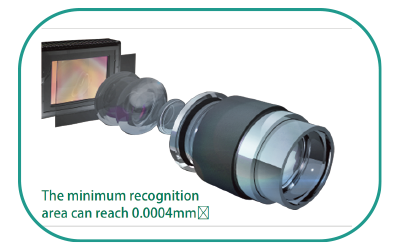

Meyer Ultra HD Imaging System

Low-distortion camera lens, with ultra-high-definition resolution, ensure clearer identification of materials

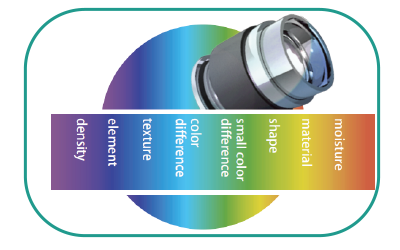

Meyer Multispectrum Confocal System

Meyer multispectrum confocal system provides multi-dimensional sorting and detection solutions such as color, shape, texture, material, etc. to meet users’ differentiated processing needs.

Smart Alarm

When the color sorter machine detects an irregularity or malfunction during the sorting process, the Smart Alarm instantly activates

Specification & Configuration

Name | Model | Ejectors | Power | Voltage | Air Pressure (Mpa) | Air Consumption | Weight | Dimension |

120SCG.A | 6SXZ-120CG2 | 120 | 1.3 | 180~240 (50Hz) | 0.6~0.8 | <2.0 | 750 | 1299×1564×2020 |

240SCG.A | 6SXZ-240CG2 | 240 | 2.0 | 180~240 (50Hz) | 0.6~0.8 | <3.0 | 1120 | 1891×1564×2020 |

360SCG.A | 6SXZ-360CG2 | 360 | 2.7 | 180~240 (50Hz) | 0.6~0.8 | <4.0 | 1400 | 2533×1564×2020 |

480SCG.A | 6SXZ-480CG2 | 480 | 3.4 | 180~240 (50Hz) | 0.6~0.8 | <5.0 | 1750 | 2991×1564×2020 |

600CG.A | 6SXZ-600CG2 | 600 | 4.0 | 180~240 (50Hz) | 0.6~0.8 | <6.0 | 2090 | 3583×1564×2020 |

780CG.A | 6SXZ-780CG2 | 780 | 5.0 | 180~240 (50Hz) | 0.6~0.8 | <7.5 | 2800 | 4445×1564×2020 |

ITEM | CG.A | ||

Performance | Key Components | NIR INfrared System | ○ |

In GaAs Infrared System | ○ | ||

15-inch LCD Screen | ● | ||

Micron-sized superior HD color Sensor | ● | ||

Compound lighting system | -- | ||

Crash-prevented maglev ejector | ● | ||

New prism spectroscopic imaging technology | -- | ||

Exclusive color | Targeted positioning | ● | |

Gentle removal | ● | ||

Shape sorting | ★★★★ | ||

Impurity Removal | Impurities (plastics, stones, desd insects, glass) | ★★★★ | |

Service Life | Patented maglev ejector | ★★★★★ | |

LED | ★★★★★ | ||

Air Circuit System | Enhanced point-to-point dust sucking system | ● | |

Upper vaccum system | ○ | ||

Machine Protection | Input protection cover | -- | |

Remote sepration chamber protection | -- | ||

Worry-free transmission structure | -- | ||

Waterproof and dustproof IP65 | -- | ||

Intelligence | IntelligenceIntelligent System | Extra-simple interface | ● |

Sorter care | ● | ||

Remote control | ● | ||

Remote commission | ● | ||

Intelligent backup | ● | ||

Intelligent self-check | ● | ||

The maglev ejector and LED can work throughout color sorters’ life under ideal conditions. | |||

REFINED SERVICES

HELP DESK SERVICE

Remote trouble shooting service Online machine adjusting service Faulty escalation service

PRE-SALE SERVICE

Consulting Solution Service Configuration Suggestion Layout Suggestion

ONSITE SERVICE

Onsite routing inspection, Onsite commissioning service, Onsite trouble shooting service, Onsite recovery service

WARRANTY SERVICE

Standard warranty service, Long term warranty service, SLA service, Over warranty service

TRAINING SERVICE

Local training service, High level headquarter service

SPARE PARTS SERVICE

Risky spare part supply, Warranty spare parts service, Key parts maintenance service, Over warranty spare parts service

NICPL

Our Locations

Our Kundli Office

206, Phase 2, HSIIDC, Industrial Area, Kundli, Sonipat, Haryana 131028