Optimize Sorting Efficiency with Our Advanced Color Sorter Machines

Whether you need to sort grains, rice, pulses, plastics, seeds, or other materials, our color sorter machines offer customizable options to suit your specific requirements.

Kaeser Screw Compressors

NICS strong technical acumen, broad network and global experience allow us to deliver sustainable solutions across the entire project stages from suggesting the right product to its deployment, service and maintenance Our team helps at every stage starting from the selection of plant and machinery, procurement, setup and comissioning of the plant and then supporting you throughout the life cycle of the product

Rotary Screw Compressors

Whether a complete compressed air station or a single compressor, our liquid injection screw compressors deliver excellent efficiency throughout their service life.

•Low life-cycle costs

• From 2.2 to 500 kW

• For reliable operation in ambient . temperatures up to 45 °C

Process-sure air purity – produced reliably and efficiently

•Uncompromising efficiency

•Service-friendly design

•Optionally available with innovative IHOC drying technology or energy- saving refrigeration dryer

Our energy-saving complete solution for generating low vacuum

•Connect and go

•With efficient IE3 motors

•Intake capacity: 4.75 to 15.70 m³/min- 99% final vacuum

Screw compressors convert 100% of the electrical energy taken into heat. Up to 96% of this energy can be recovered.

Modern screw compressors are

particularly well suited for heat recovery due to their fully enclosed design. This applies to both liquid injection and oil-free compressors.

CONTROLLERS

Our product range includes

→ Compressor controllers for demand-oriented compressor performance optimisation

→ Master controllers for complete system optimisation

Master Controller: SIGMA AIR MANAGER 4.0

The next generation of compressed air management master system, the SIGMA AIR MANAGER 4.0.

Compressor Controller: SIGMA CONTROL 2

The SIGMA CONTROL 2 unit coordinates compressed air generation and consumption. With its intelligent control, this advanced system prevents inefficient energy usage, especially in partial load operation.

BLOWERS

Our product range includes

→Rotary lobe blowers with minimal pulsation OMEGA rotors – from single blocks to large packages

→Rotary screw blowers with energy-saving SIGMA profile airends

→After coolers for process air cooling and heat recovery

Durable Space-Savers

→Flow rate 160 m³/min .Robust and durable

→More efficiency, even more versatile

→Optionally available with control cabinet

For installation in OEM system solutions

- For highly diverse applications – from vapour compression in vacuum distillation and applications in the fine vacuum range to nitrogen conveying.

- Also suitable for mobile applications – e.g. mixing, tanker and suction vehicles

- Intake volume of 5 to 160 m³/min at pressures up to 1 bar (g), or 0.5 – 0.9 bar (vacuum).

Introducing our compact dryers, the Kaeser Membrane Module (KMM). They offer superior efficiency and reliability with a unique flow concept and high-density helical fiber structure. Despite their small size, KMM dryers achieve sub-zero pressure dew points and are perfect for space-limited installations. Experience efficient drying and reliable performance with our compact KMM dryers. Upgrade your compressed air system today!

Upgrade to our ISO 8573-1 compliant filters for superior protection of sensitive production processes. With high-quality activated carbon, they offer long-lasting durability and low pressure loss, saving costs. Our filters last up to 12,000 hours without activated carbon replacement. Standard oil indicator ensures operational reliability. Experience optimal performance and efficiency with our Activated Carbon Absorber.

Experience Kaeser Kompressoren’s desiccant dryers that reach impressive pressure dew points as low as -70 °C. Our dryers offer reliable anti-frost protection for your control valves and lines, ensuring smooth operation. With standard-equipped high-quality compressed air filters and energy-saving controllers, you can achieve compressed air drying for sensitive processes while minimizing costs. Upgrade to our efficient and cost-effective desiccant dryers today!

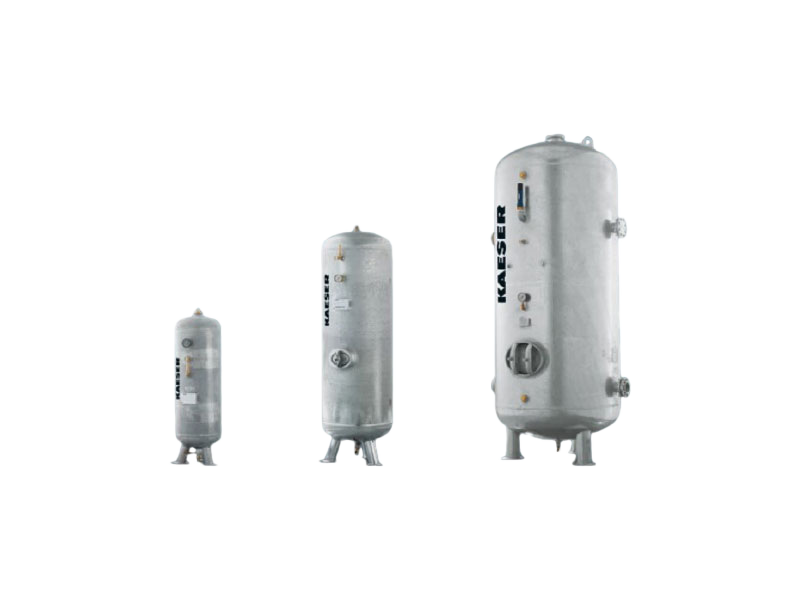

Vertical or horizontal air storage-up to 50 bar Air receivers are an important link in the compressed air chain: as storage media or buffers for peak load demand. With Kaeser air receivers, you are always on the safe side technically: because we look at the overall system, we focus on perfectly matched easy installation and a comprehensive range of accessories