Our Double Body Paddy Separator is a game-changer in rice processing, delivering exceptional results in separating paddy from brown rice. With its advanced design and efficient operation, it effectively removes impurities, ensuring high-quality output.

Rice and pulses often contain unwanted elements such as dust, dirt, stones, straw, and other foreign materials. These impurities can affect the taste, appearance, and overall quality of the rice and pulses, as well as damage the processing machinery. That’s why we use pre-cleaner.

Paddy huskers are an important component in the rice milling process, as they help prepare the paddy for further processing. Once the husk is removed, the rice can undergo additional steps such as whitening, polishing, and sorting to produce the final polished rice that is commonly consumed.

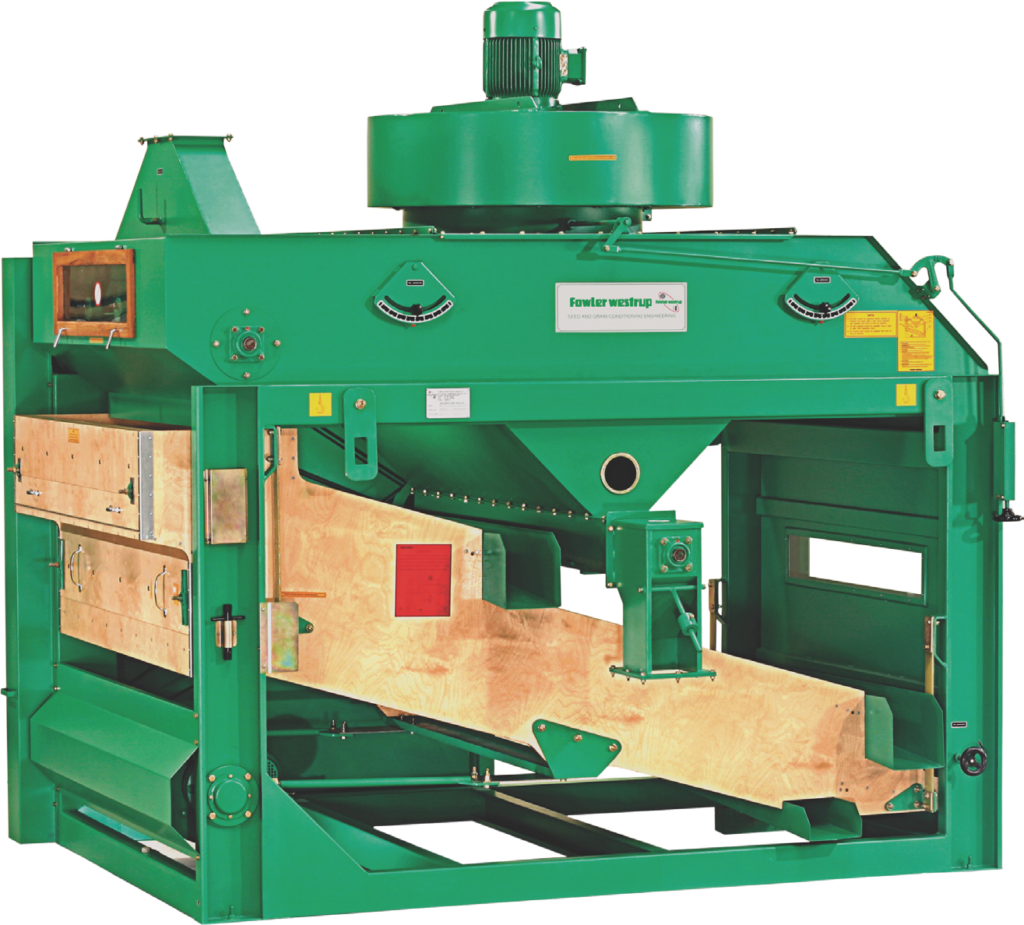

In the agricultural industry, destoners are commonly used in the cleaning and processing of various crops, such as rice, wheat, corn, soybeans, and pulses. They help remove stones, clods of soil, sand, and other heavy debris that can be harmful to downstream equipment and affect the quality of the final product.